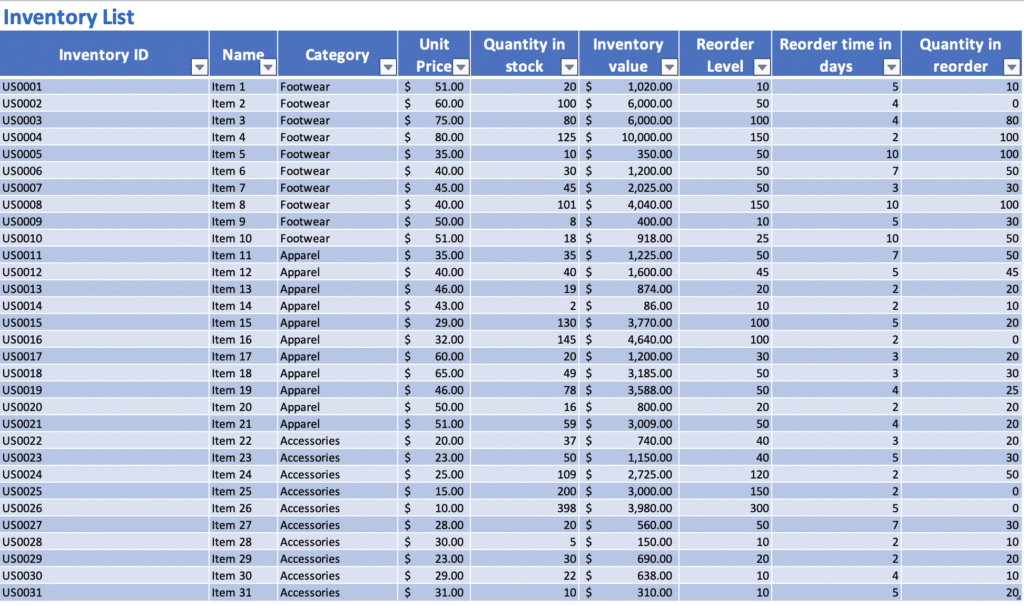

The average lead time can be calculated from the amount of time your vendor has taken to deliver the products in the past. Lead time demand is calculated by multiplying average lead time in days with average daily sales. Lead time demand = average lead time in days x average daily sales Without this calculation, you run the risk of going out of stock on items while you are waiting for new ones. To avoid a stockout, you need to predict the product demand during that time. Lead time is the amount of days it takes for your vendor to fulfill your order. To use the inventory forecasting formula, we must do the following:Ĥ. Calculate safety stock Calculating lead time demand

Inventory forecasting uses factors such as sales history and trends, average lead time, demand, reorder point, and safety stock to predict inventory levels. This frees up warehouse space and increases revenue.

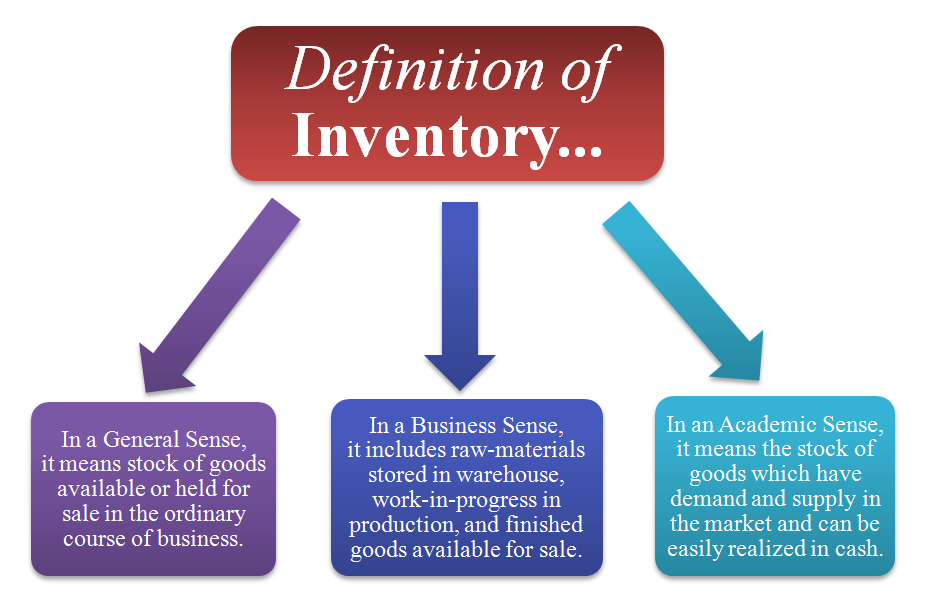

Based on this, you can plan to re-purpose these items or bundle them with better selling products. Inventory forecasting reveals which items are not selling or which are selling slower. It helps with inventory storage space management because you buy only what you need and stock only those products instead of ordering too much. This in turn reduces the unwanted storage space and the costs incurred along with it. Inventory forecasting helps with overall inventory management. With this information, you can better understand when to restock and how many units to order. Inventory forecasting helps you avoid this by accurately predicting future demand. Benefits of inventory forecasting Minimizes stockouts It is a great inventory management tool that can increase your company’s revenue and decrease unnecessary costs. It also helps keep track of sales and demand so you can better manage your purchase orders. Inventory forecasting is a method used to predict inventory levels for a future time period.

0 kommentar(er)

0 kommentar(er)